Chapter 5 Research and Development

5.1 Sentiment Analysis

5.2 Six Sigma

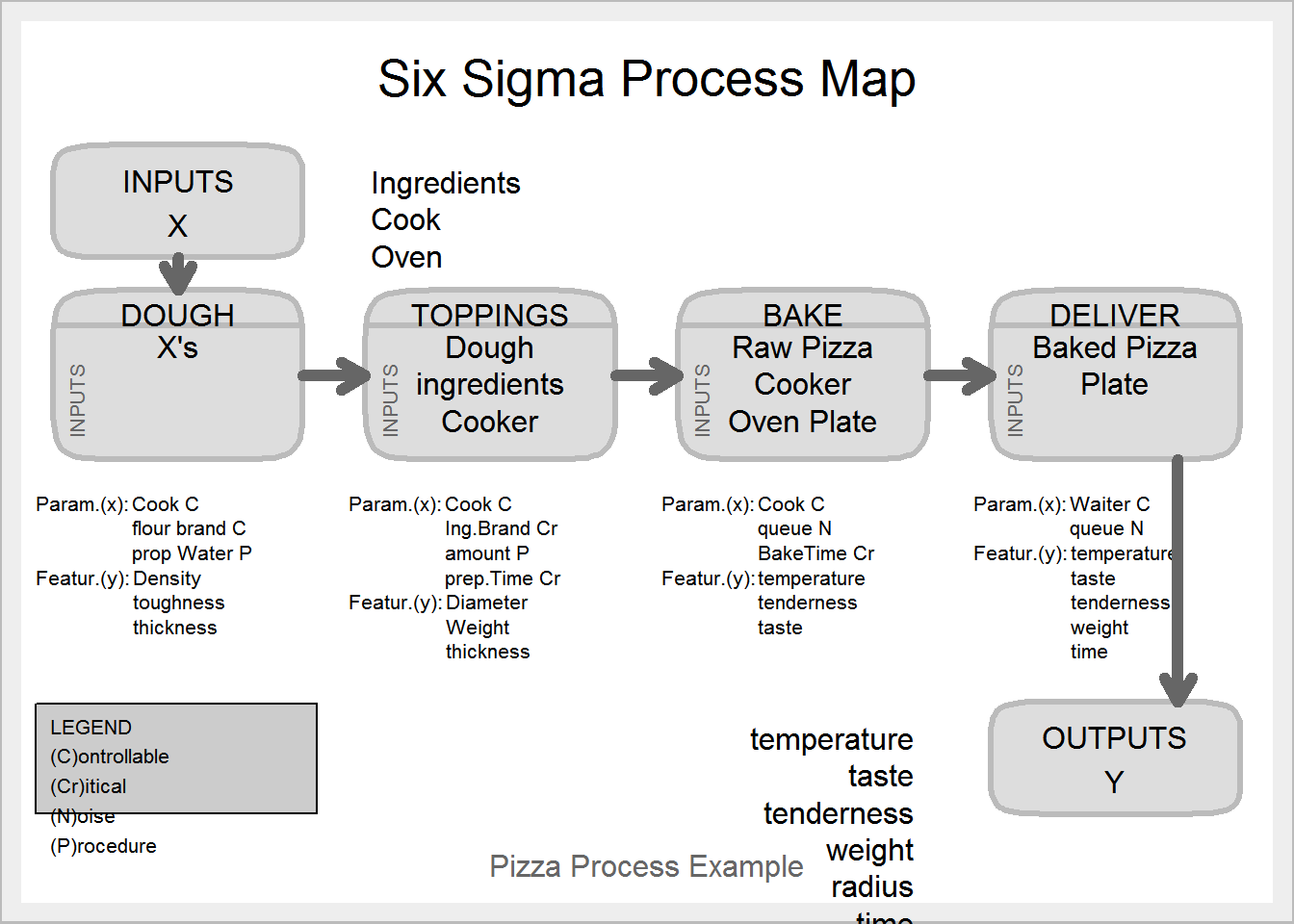

library("SixSigma")

# Create vector of Input , Output and Steps

inputs <-c ("Ingredients", "Cook", "Oven")

outputs <- c("temperature", "taste", "tenderness","weight", "radius", "time")

steps <- c("DOUGH", "TOPPINGS", "BAKE", "DELIVER")

#Save the names of the outputs of each step in lists

io <- list()

io[[1]] <- list("X's")

io[[2]] <- list("Dough", "ingredients", "Cooker")

io[[3]] <- list("Raw Pizza", "Cooker", "Oven Plate")

io[[4]] <- list("Baked Pizza", "Plate")

#Save the names, parameter types, and features:

param <- list()

param[[1]] <- list(c("Cook", "C"),c("flour brand", "C"),c("prop Water", "P"))

param[[2]] <- list(c("Cook", "C"),c("Ing.Brand", "Cr"),c("amount", "P"),c("prep.Time", "Cr"))

param[[3]] <- list(c("Cook","C"),c("queue", "N"),c("BakeTime", "Cr"))

param[[4]] <- list(c("Waiter","C"),c("queue", "N"))

feat <- list()

feat[[1]] <- list("Density", "toughness", "thickness")

feat[[2]] <- list("Diameter", "Weight", "thickness")

feat[[3]] <- list("temperature", "tenderness", "taste")

feat[[4]] <- list("temperature", "taste", "tenderness","weight", "time")

# Create process map

ss.pMap(steps, inputs, outputs,io, param, feat,sub = "Pizza Process Example")

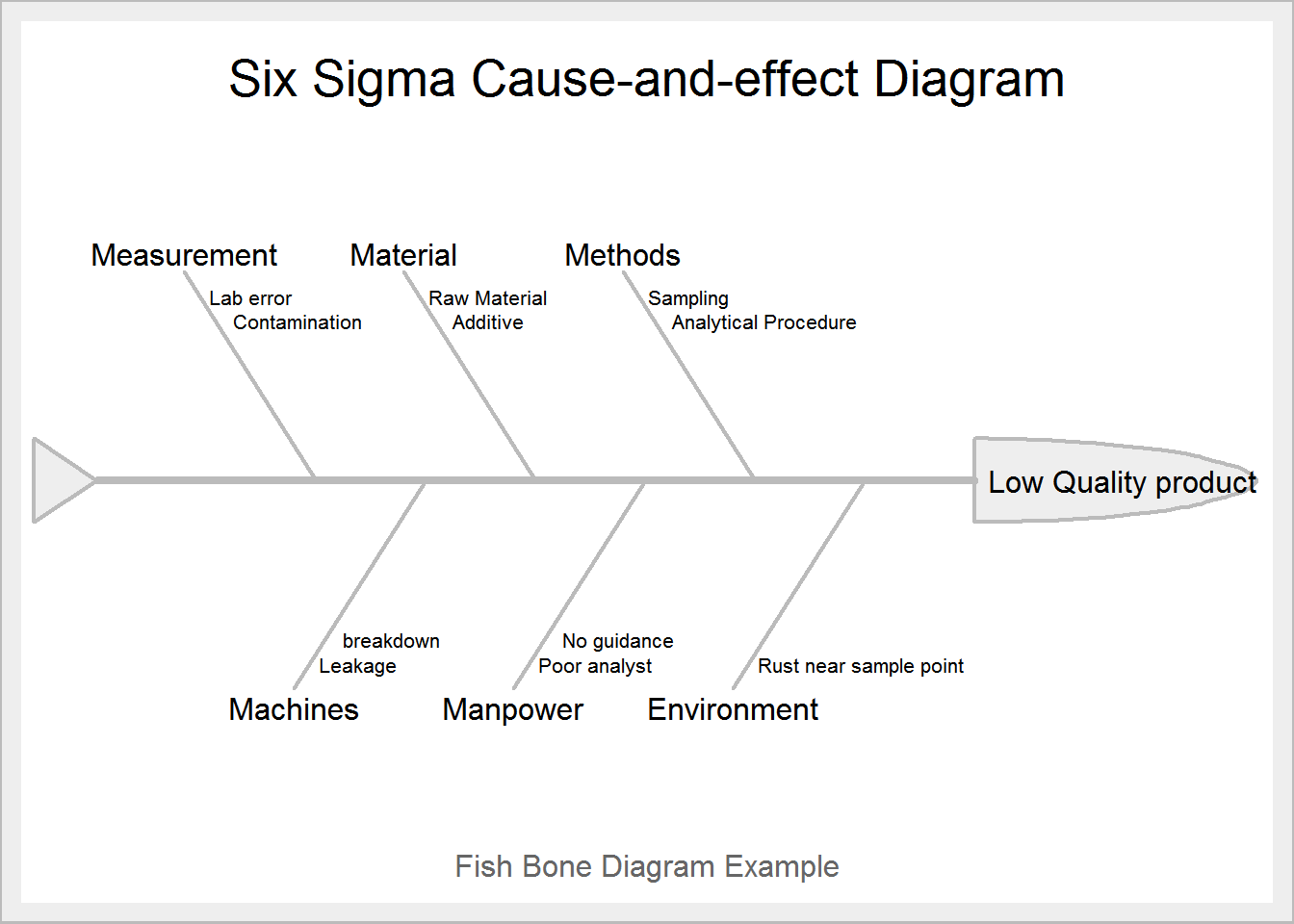

# Cause and Effect Diagram

##Create effect as string

effect <- "Low Quality product"

##Create vector of causes

causes.gr <- c("Measurement", "Material", "Methods", "Environment",

"Manpower", "Machines")

# Create indiviual cause as vector of list

causes <- vector(mode = "list", length = length(causes.gr))

causes[1] <- list(c("Lab error", "Contamination"))

causes[2] <- list(c("Raw Material", "Additive"))

causes[3] <- list(c("Sampling", "Analytical Procedure"))

causes[4] <- list(c("Rust near sample point"))

causes[5] <- list(c("Poor analyst","No guidance"))

causes[6] <- list(c("Leakage", "breakdown"))

# Create Cause and Effect Diagram

ss.ceDiag(effect, causes.gr, causes, sub = "Fish Bone Diagram Example")

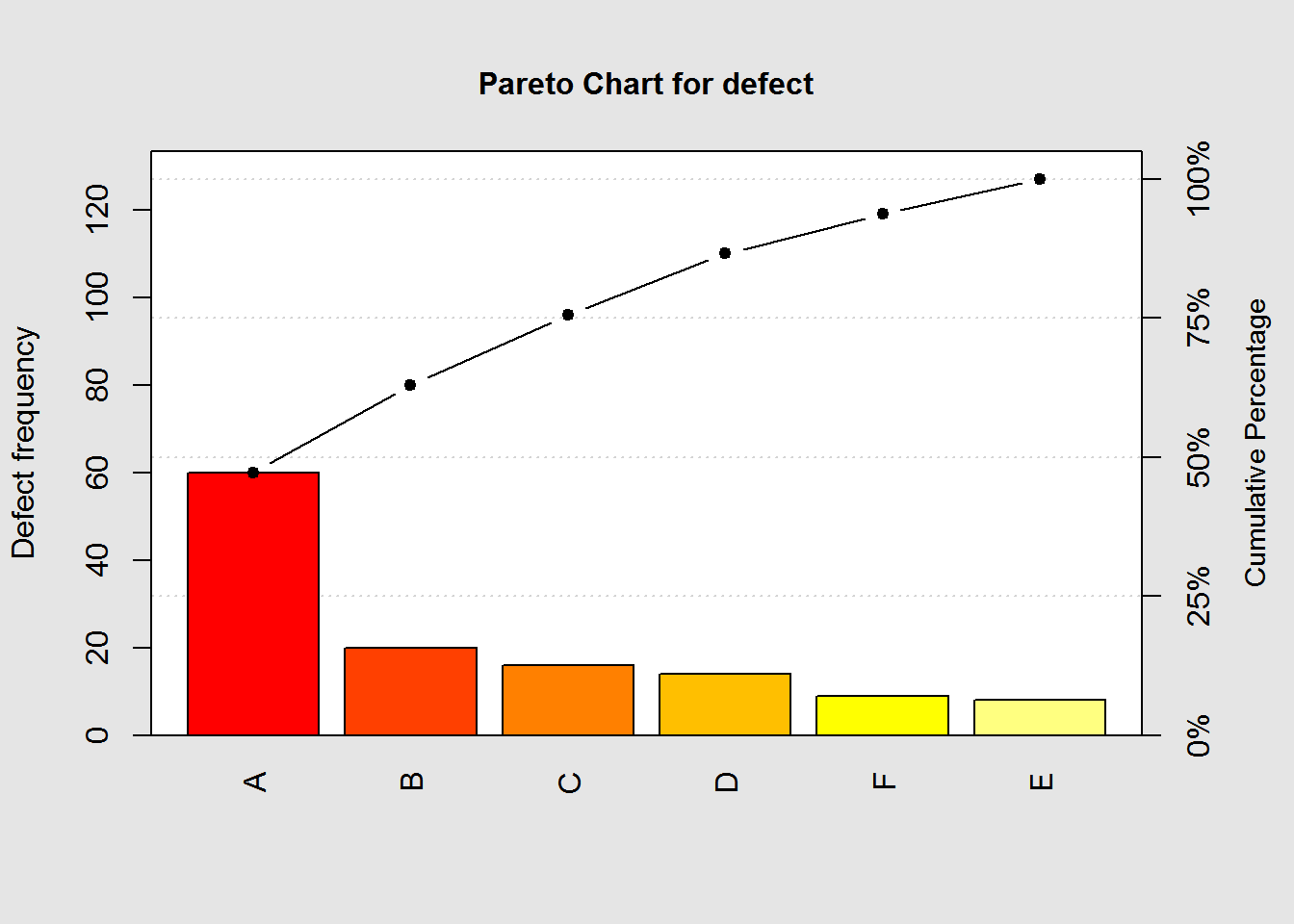

#Pareto Chart

library(qcc)

defect <- c(60,20,16,14,8,9)

names(defect) <- c("A", "B", "C", "D","E","F")

pareto.chart(defect, ylab = "Defect frequency", col=heat.colors(length(defect)))

Pareto chart analysis for defect Frequency Cum.Freq. Percentage Cum.Percent. A 60.000000 60.000000 47.244094 47.244094 B 20.000000 80.000000 15.748031 62.992126 C 16.000000 96.000000 12.598425 75.590551 D 14.000000 110.000000 11.023622 86.614173 F 9.000000 119.000000 7.086614 93.700787 E 8.000000 127.000000 6.299213 100.000000

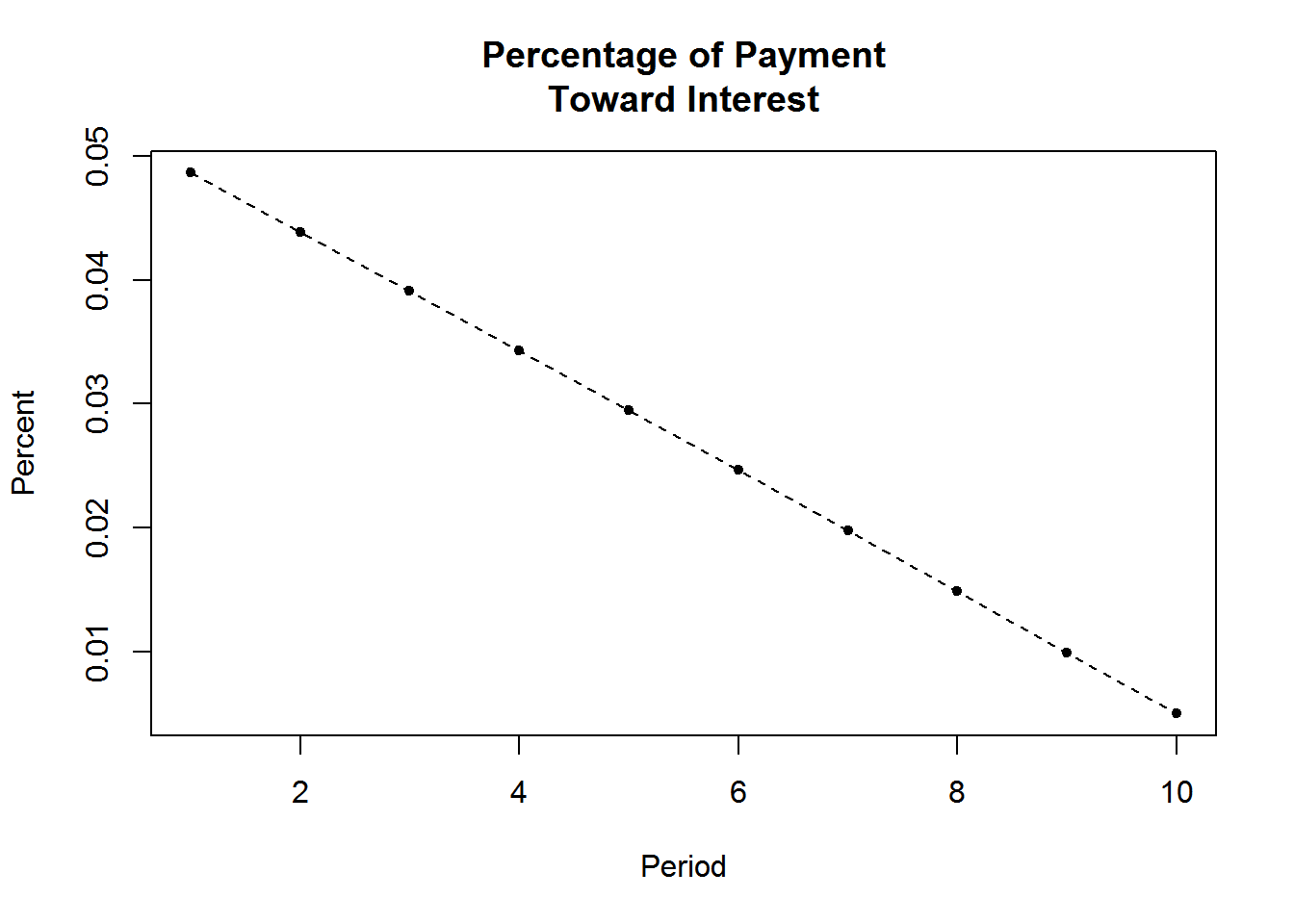

curve(0.002 * (x - 10)^2, 9, 11,

lty = 1,

lwd = 2,

ylab = "Cost of Poor Quality",

xlab = "Observed value of the characteristic",

main = expression(L(Y) == 0.002 ~ (Y - 10)^2))

abline(v = 9.5, lty = 2)

abline(v = 10.5, lty = 2)

abline(v = 10, lty = 2)

abline(h = 0)

text(10, 0.002, "T", adj = 2)

text(9.5, 0.002, "LSL", adj = 1)

text(10.5, 0.002, "USL", adj = -0.1)

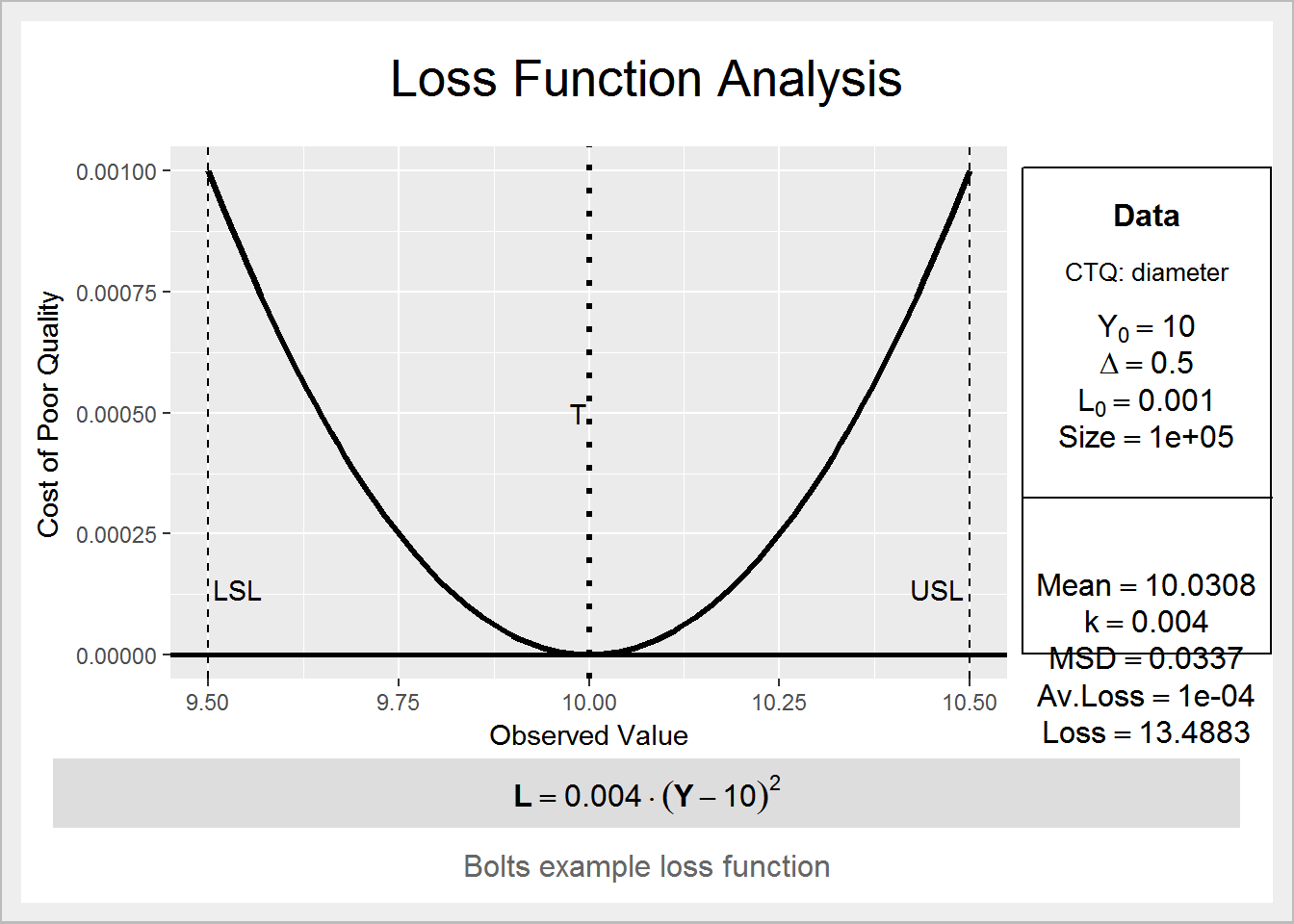

# Create loss function with Tolerance=0.5 ,target=10,Cost of poor quality=0.001,batch size=100000)

ss.lfa(ss.data.bolts, "diameter", 0.5, 10, 0.001,lfa.sub = "Bolts example loss function",

lfa.size = 100000, lfa.output = "both") $lfa.k [1] 0.004

$lfa.k [1] 0.004

$lfa.lf expression(bold(L == 0.004 %.% (Y - 10)^2))

$lfa.MSD [1] 0.03372065

$lfa.avLoss [1] 0.0001348826

$lfa.Loss [1] 13.48826