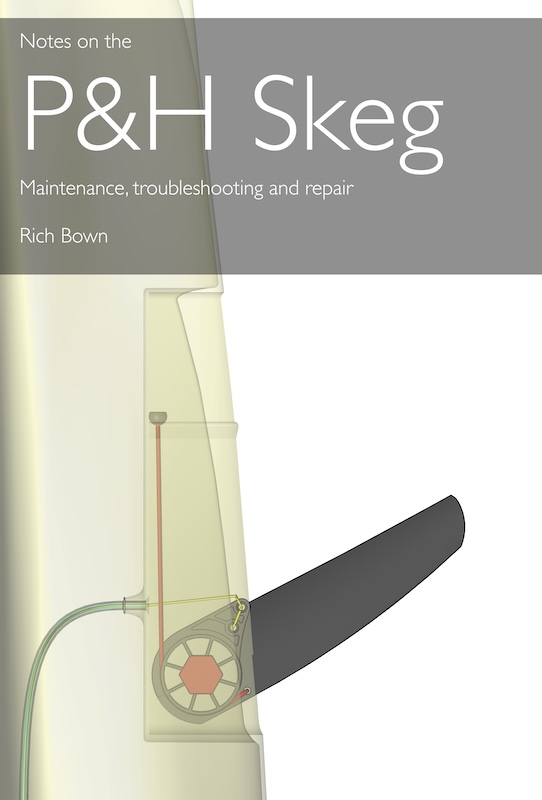

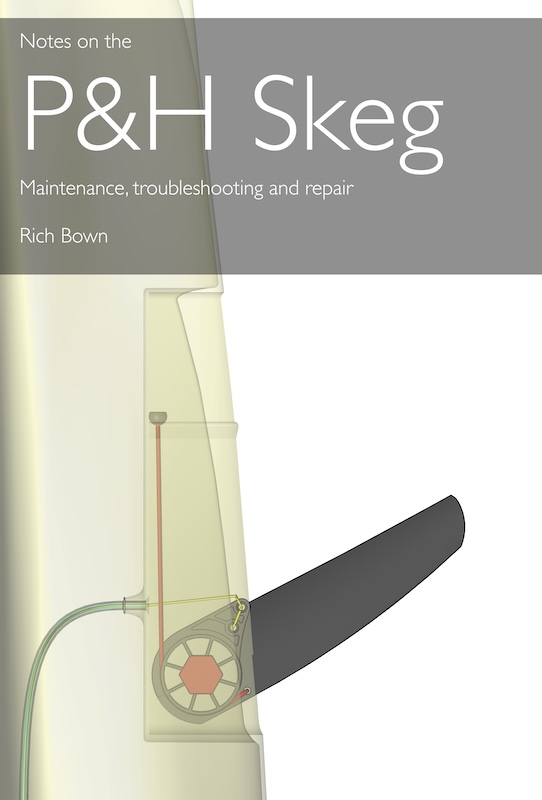

P&H skeg

Maintenance, troubleshooting and repair

1 Old version

The bookdown.org hosting service is being decommissioned.

This book has been moved to here.

Maintenance, troubleshooting and repair

The bookdown.org hosting service is being decommissioned.

This book has been moved to here.